The manufacturing industry has evolved rapidly, with efficiency and durability at the core of its advancements. One of the key drivers of this evolution is the use of high-performance materials that enhance product longevity, precision, and operational efficiency.

From aerospace components to industrial tooling, material selection is not just about cost but about performance and reliability. For startups and manufacturers aiming to stay competitive, understanding these materials is essential.

Why High-Performance Materials Matter in Manufacturing

The foundation of any successful manufacturing operation lies in choosing the right materials. Industrial applications demand materials that can withstand extreme temperatures, wear, and heavy usage without compromising performance.

Sectors such as aerospace, automotive, and medical device manufacturing rely on high-performance materials to maintain structural integrity while reducing weight. These materials don’t just enhance product performance; they reduce downtime and maintenance costs, giving businesses a competitive edge.

For startups entering the manufacturing space, selecting the right materials early on can prevent costly redesigns and production inefficiencies down the line.

The Role of Carbide in Precision Manufacturing

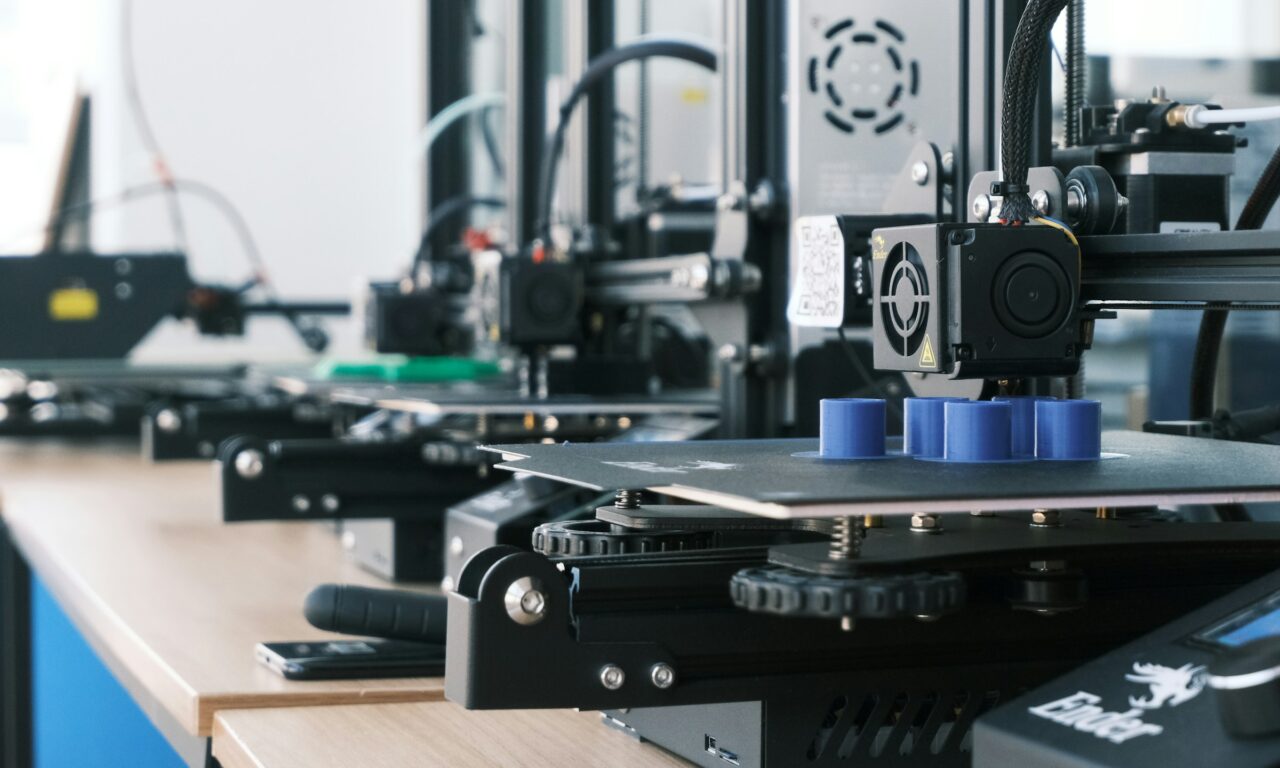

One of the most widely used high-performance materials in manufacturing is carbide. Known for its extreme hardness and wear resistance, carbide is an essential material for cutting tools, metalworking, and precision machining. Unlike conventional steel, carbide tools retain their sharpness longer and perform well under high-speed and high-temperature conditions.

For manufacturers that require precision, durability, and minimal downtime, investing in high-quality carbide components is a necessity. A trusted carbide manufacturer can supply reliable tools that maintain consistent quality, reducing the risk of product failures or machining errors.

Quality Control in Your Production: The Key to High-Performance Manufacturing

Quality control is a critical factor in leveraging high-performance materials effectively. Even the best materials will fail if not handled, tested, and implemented correctly in production. Strict material verification, process monitoring, and end-product testing ensure that manufacturers maintain high standards.

For startups, maintaining quality control presents a unique challenge. While manufacturing your product in-house offers control over materials and processes, it also requires significant investment in equipment and expertise. On the other hand, outsourcing can reduce overhead costs but demands careful selection of suppliers who uphold strict quality standards. Manufacturing your product has its pros and cons, especially when ensuring consistent quality with high-performance materials.

How Startups Can Leverage High-Performance Materials for Growth

Startups entering the manufacturing sector must be strategic about material selection and supplier partnerships. While large manufacturers have established supply chains, startups often need to balance cost-efficiency with material quality to remain competitive.

Building strong relationships with reliable material suppliers is a smart move. Investing in research and development to explore innovative material applications can also give startups a market advantage. With advancements in composite materials, carbide tooling, and lightweight alloys, emerging manufacturers have more opportunities than ever to improve efficiency without sacrificing quality.

High-performance materials are shaping the future of manufacturing, improving precision, durability, and cost-effectiveness. Whether using carbide for cutting tools or advanced composites for aerospace applications, material selection plays a defining role in efficiency and product longevity.

For startups and established manufacturers alike, the key to success lies in quality control, strategic material sourcing, and a forward-thinking approach to innovation. By leveraging advanced materials, businesses can maximize productivity while staying ahead in a rapidly evolving industry.